At the Campus of the University of Castilla La Mancha (UCLM) in Spain, the XI National and II International Engineering Thermodynamics Congress has taken place with the sponsorship of CADE and other companies and institutions from the Renewable Energy Sector.

Since more than twenty years, every two years, this congress has been a unique meeting point for researchers, university teachers and professionals in this topic. Furthermore, since 2017, the congress has an increasing international participation, welcoming experts from different countries to share experiences that could improve teaching and researching techniques at different fields in which Engineering Thermodynamics plays an important role.

From June 12th to 14th, more than 160 engineering experts had the opportunity to share their experiences and discuss with others during the congress, whose program was carried out around the following topics:

- Energy efficiency and sustainability in buildings and industry

- Energy, exergy and economic analysis and thermal power plants

- Experimental heat and mass transfer processes

- Fuels, combustion and thermal engines

- Numerical simulation and modelling

- Refrigeration, thermal comfort and air conditioning

- Renewable energies and environmental impact

- Teaching innovation

- Thermo-physical properties of materials and fluids

About CADE and Engineering Thermodynamics Services

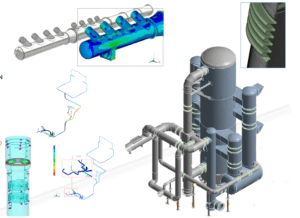

CADE provides design and engineering services for heat transfer and process equipment, as well as for other units in Oil & Power industries by playing a role of technology and engineering partner for manufacturing companies, EPC contractors and plant owners.

Engineering and design services range from process, thermal, hydraulic and detailed mechanical design, to procurement, commissioning and process performance advisory:

- Thermal and Hydraulic design and plant process integration

- Mechanical design

- Detail engineering. Manufacturing drawings

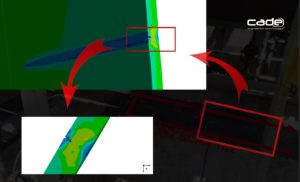

- CFD simulation of heat transfer and flows performance.

- FEM advanced analysis

- CHT studies (Conjugated Heat Transfer).

- Advisory around underperformance, heat losses, performance reduction and Troubleshooting of existing equipment